6 Watertight Floor and Wall Coverings and Paint Systems

This section discusses how watertight floor and wall coverings and paint systems are installed. In this section, the term covering is used for both walls and floors.

Watertight floor and wall coverings and paint systems are designed to protect underlying building parts against moisture (see Section 2.2.2, Watertightness).

Table 3 in Section 3.1.4 and Tables 6 and 7 in Section 4.1.2 provide an overview of where watertight floor and wall coverings and paint systems are required on floors and walls, respectively.

6.1 Types of Wall Coverings

A construction can be waterproofed with:

- A watertight tile setting and covering system (i.e., a waterproofing membrane, perhaps applied in liquid form, protected against mechanical impact from tiles or other ready-made surface covering)

- A watertight covering (e.g., a PVC covering with watertight joints)

- A wet room paint system (i.e., a total system of paint products, such as primer, adhesive, fibre-glass fabric, and paint, which together form a watertight surface)

Manufacturer’s instructions must always be observed (e.g., when making joints and penetrations). Materials from various manufacturers or systems must not be combined, as no documentation exists to validate the efficacy of such combinations.

6.2 Watertight Membranes and Covering Systems

6.2.1 Build-up

Watertight tile setting system is the term used for waterproofing kits,

typically consisting of:

- primer, waterproofing membrane with recommended waterproofing tape, sleeves, tile adhesive, tiles, tiling grout, and possibly sealant

- a prefabricated waterproofing membrane with ancillary adhesive and other accessory materials

The tile covering is meant to protect the watertight membrane against mechanical load.

Watertight tile setting systems for use on organic substrates, stud walls, and other elements, must meet the specific criteria for achieving an ETA or MK approval (see Annex E. Marking and Approvals). These requirements include water impermeability, water-vapour impermeability, adhesion, layer cohesion, and resistance to shocks and blows, for example. The requirements for watertight tile setting systems are specified in MK 7.00/012, Vægbeklædninger til vådrum. MK prøvnings- og godkendelsesbetingelser (Wall Coverings for Wet Rooms. MK Testing and Approval Conditions) (ETA-Danmark, 2014b).

Figure 75. An example of typical work processes for stud wall and floor used as substrate for a watertight tile setting system where the membrane is applied in liquid form. Floor and wall surface areas must be stable, clean, and sufficiently strong to hold the subsequent waterproofing membrane and tile covering. All sheet joints on the walls and transitions between floor and walls are sealed with mesh reinforcement. Sleeves are fitted (depending on the system) around floor outlets and pipe penetrations. Finally, the waterproofing membrane is applied, and the tiles are mounted.

The substrate is normally prepared by flashing corner joints, connections, floor-wall transitions, pipe penetrations, reinforcing them with reinforcement mesh or special sealing tape and sealing collars.

6.2.2 Tiling

Currently, tile adhesive is almost always used for tiling floors and walls, but it is still acceptable to use mortar. However, mortar cannot be used with approved tile setting systems, all of which require the use of tile adhesive.

Floor-tiling is normally performed on a substrate incorporating the correct falls towards the outlet, as only modest adjustments to falls are feasible with tile adhesive. Falls can be constructed in the substrate in various ways, depending on the specific conditions (see Section 3, Floor Constructions).

The following requirements apply when mounting or laying tiles:

- Surface areas must be clean and dust-free.

- Tile adhesive is applied in the quantity specified by the manufacturer. The quantity depends on the type of tile, including the geometry of its reverse side, which can be smooth or embossed.

- The tile adhesive must be applied so that it covers the entire surface area. The tile adhesive is normally applied using a notched trowel to adjust the amount of adhesive required.

- The tiles are mounted so that the whole of its reverse side is covered (e.g., by ’twisting’ the tile into position). Now and again, a tile should be ’slaughtered’ to check that its reverse side is totally covered with adhesive.

- If tiles are big, it may be necessary to use adhesive on both the substrate and tile to ensure full adhesive coverage.

Adaptations will normally have to be made to tiles by cutting them. It will usually look best if cut tiles at the perimeter are uniform and not too small. It is a good idea, therefore, to mount the tiles from the centre of the room, so that the width of the cut tiles is uniform on both sides. When testing a layout, ensure that all tiles that need cutting are bigger than half a tile (see Figure 76). There may be other reasons, such as adaptations around doors and windows, which dictate that the tiles be laid differently. In this case, tiles may also be cut to fit around windows or doors.

Figure 76. Laying tiles. Tiles should be cut to a size bigger than half a tile. If laying them from the centre of the room does not always result in tiles being > ½ tile, if necessary stagger the tiles by a ½ tile relative to the centre of the room.

If the format for wall and floor tiles is identical, the joints should line up in the transitions as far as possible.

It is difficult to lay large tiles completely evenly. This is because small irregularities, such as curvature in the tile, thickness tolerances, and minor distortions in tiles when laying them will result in substantial unevenness at tile edges. Furthermore, it is difficult to construct falls towards traditional floor outlets. For these reasons, tiles should be no bigger than approx. 200 × 200 mm, unless they are laid with tapered falls (i.e., laid along the fall lines). Alternatively, trench or corner outlets can be installed in which case the floor area can be made plane but with an overall incline towards the floor outlet.

Although every effort is made to lay the tiles such that they are fully covered with adhesive, so-called ‘drummy’ tiles may appear. These are tiles with a partially hollow space underneath them. Drummy tiles have no bearing on watertightness, since it is not the tiles that make the floor watertight. However, the tiles must stick.

The thickness of floor tiles should be min. 5 mm. The water absorption of tiles should be max. 10 % according to DS/EN ISO 10545-3:1997 (Danish Standards, 1997). Hard-fired tiles with max. 6 % water absorption are used for floors with underfloor heating.

Further information on tiles is available in the publications Fliser på gulv og vægge (Tiles on Floors and Walls) (Brandt, 2006), Fliser og klinker (Tiles and Clinker Bricks) (Hansen, Andreasen & Hansen, 2009), and the BYG-ERFA info sheets Fliser på vægge og gulv – underlag, fliseklæber og fliser (Tiles on Walls and Floors – Substrates, Adhesives, and Tiles), (42) 05 04 11, Misfarvning af fuger i vådrum – årsager, forebyggelse og udbedring (Discolouring in Wet Rooms – Causes, Prevention, and Repair), and (43) 01 03 01, Keramiske fliser og klinker – lægning af gulve i cementmørtel (Ceramic Tiles and Clinker Bricks – Laying Floors in Cement Mortar) (Byg- Erfa, 2014; 2011; 2001).

6.2.3 Tile Coverings in Wet Zones

On stud walls and floor and wall constructions containing organic materials in the wet zone, tile setting systems with an ETA or MK approval for use with the material in question must be used (see Table 3 in Section 3.1.4 and Table 6 in Section 4.1.2.).

The tile setting system must have a proper watertight layer in the form of a membrane. Membranes applied in liquid form must have a thickness of min. 1.0 mm. Prefabricated membranes could be thinner than 1.0 mm, but must be sufficiently robust to resist minor shocks and blows during the construction process. Those primers, waterproofing tapes, collars, waterproofing membranes, adhesives, tile adhesives, tile grouts, etc., specified by the chosen watertight tile setting system must be used because the approval applies to the system. The quantity of materials, curing times, etc., specified in the approval must be adhered to. This means that the liquid membranes must be applied in the correct quantity to obtain the required layer thickness of 1.0 mm (in dry conditions). The approval of the tile setting system applies solely to the substrates mentioned in the approval.

6.2.4 Tile Coverings in Humid Zones

In the humid zone, it is possible to use all the tiling systems approved for use in wet zones. Furthermore, other systems may be used (e.g., systems where the primer and adhesive together provide the wall’s watertight layer without an actual membrane, as such).

Tile setting systems for use in humid zones might have an ETA or MK approval (e.g., a system with a thinner membrane or completely without a membrane), but such an approval is not a requirement. However, manufacturers must always be able to document that the product meets the standards required for obtaining an approval (see MK 7.00/012, Vægbeklædninger til vådrum. MK prøvnings- og godkendelsesbetingelser (Wall Coverings for Wet Rooms. Conditions for MK Tests and Approvals) (ETA-Danmark, 2014b)).

A tile setting system without an approval can only be used on stud walls with a substrate of wet room plasterboard, fibre plasterboard, or calcium silicate sheets mounted either as outlined in Section 4, Walls, or on walls constructed according to a separate ETA or MK approval.

The primers, tile adhesives, tile grouts, etc., specified for the system in question must be used. The same is true of the quantities of material and curing times, etc., stated in the mounting instructions or the approval.

Figure 77. An example of a joint between a stud wall (with two layers of sheets with a watertight approved tile setting system with a membrane) and a plywood subfloor (with PVC floor covering). The wall waterproofing membrane overlaps the upturned PVC floor covering by 50 mm. Filler is applied to the wall above the upturned floor covering to achieve an even transition and the covering is primed. Above the filling and in the flashing, a mesh strip has been fitted to achieve good adhesion between the tile setting system’s waterproofing membrane and the floor covering. The tile covering finishes 100 mm above the floor to protect the tile edge against splashback, shocks, and blows.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 78. An example of a joint between a stud wall (with two layers of sheets with a watertight approved tile setting system with a membrane) and a plywood subfloor (with prefabricated waterproofing membrane). The wall waterproofing membrane overlaps the prefabricated floor waterproofing membrane by 50 mm. The floor membrane finishes 100 mm above finished floor level. Filler is applied to the wall above the upturned tanking membrane to achieve an even transition. Above the filling and in the flashing, mesh sealing tape has been fitted to achieve good adhesion between the tile setting system’s tanking membrane and the floor tanking membrane. The floor tiles are bonded to the screed. A flexible mortar joint has been made in the transition between floor and walls.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 79. An example of a joint between a stud wall (with two layers of sheets) and a plywood floor. Both floor and walls are waterproofed with an approved tile setting tiling system with a waterproofing membrane. A liquid sealant with a mesh reinforcement strip is applied to the joint between floor and walls as shown in the specific laying instructions. The tile setting system’s waterproofing membrane covers all wall areas and the whole floor area. The thickness of the membrane layer is min. 1.0 mm throughout. The falls in the floor are incorporated in the subfloor. A flexible mortar joint has been applied in the transition between floor and walls.

Floor |

Wall in wet zone |

Wall in humid zone |

6.3 PVC Coverings

6.3.1 Prerequisites for Using PVC

PVC floor and wall coverings (subsequently called PVC coverings) are intrinsically watertight if the correct materials are used, and the work is carried out correctly. PVC coverings for use in wet rooms must be roll material which is homogenous, or laminates of homogenous layers. They must meet the quality requirements in Table 10 and must contain max. 50 % filler in each layer for reasons of weldability.

PVC coverings meeting DS/EN ISO 10581 (Danish Standards, 2013), contain max 45 % filling material and thus meet the requirements for filling material content.

Nowhere may the coverings be thinner than 2.0 mm for floors and 1.5 mm for walls. For reasons of adhesion, they must have a planar reverse side.

Figure 80. Welding joints in resilient floor coverings. Welding joints are made at inward as well as outward corners with oblique sections made in the upturned floor covering. For pipe penetrations, the joint is offset, so that wire-welding of the joint will not be hampered by the penetration. The spacing between pipe and wall must be min. 30 mm and the penetration must be made using a watertight collar bush designed for PVC coverings.

Pipe penetrations are made watertight with collar bushes. For cast-iron discharge pipes as well as renovation tasks where pipes cannot be moved, watertight collars welded to the floor covering are used. If using PVC, the following criteria must be met:

- No joints are permitted above sheet end joints in floors or walls.

- All sheet joints must be surface-ground and then primed to reduce absorbency.

- The covering must be fully bonded to the floor and/or walls.

- The floor and/or walls must be fully covered.

- All joints in the covering must be wire-welded.

- The number of joints and pipe penetrations in the covering should be kept to a minimum.

The PVC wall covering can be welded to the PVC floor covering in a watertight joint (see Figure 80). Alternatively, an overlap joint can be made.

6.3.2 Checking the Workmanship

Work with PVC coverings should be carried out by professionals holding a welding certificate and the workmanship should be subject to strict control. The certificate documents that they have completed a course and passed a test in working with PVC wet room applications (including the construction of subfloors with falls and wire-welding coverings).

Building owners should demand documentation for the work having been checked during implementation and at the point of hand-over. This should include a final check of all outcome requirements, especially the watertightness of welded joints.

Contractors should be affiliated with an approved, external control scheme, which regularly samples work carried out, such as Gulvbranchens Vådrumskontrol (GVK) (Flooring Sector Wet Room Control). Building owners should request copies of the contractor’s report to the control scheme. The report will document that sample control has been carried out, including testing the watertightness of welded joints.

PVC coverings supplied or installed by firms affiliated to Gulvbranchens Vådrumskontrol (GVK) can be expected to meet the quality requirements listed in Table 10.

Contractors affiliated to the GVK scheme can be expected to have the work carried out by floor fitters with a welding certificate. Furthermore, the work is part of an external quality assurance scheme, implying that the regulatory body will perform regular sampling of the work carried out. Information on Gulvbranchen’s rules for delivery, installation, and external control of PVC coverings in wet rooms is available from www.gulvbranchen.dk.

Table 10. Quality requirements for PVC roll materials used as floor or wall coverings in wet rooms. The manufacturer must be able to document that the product meets the stipulated requirements and specify which ancillary materials to use with them (e.g., primers, adhesives, welding wire, and sealants).

Feature | Test Method 1) | Value |

|---|---|---|

Thickness of weldable layer | DS/EN 428 (Danish Standards, 1993b) | ≥ 2.0 mm for floors ≥ 1.5 mm for walls |

Watertightness | DS/EN 13553 (Danish Standards, 2002) | Tight |

Thermal stability | DS/EN 434 (Danish Standards, 1994) | Dimensional change ≤ 0.3 % |

Marks at indentation | DS/EN 433/IS24343-1 Danish Standards, 2012) | Depth of mark ≤ 0.8 mm |

Tensile strength of covering w. welded joint | DS/EN 684 (Danish Standards, 1996) | ≥ 8.0 N/mm |

Permanent seam strength of welded joint | DS/EN 684 (Danish Standards, 1996) | ≥ 15 % |

- See Bibliography

Examples of joints between PVC covering on walls and floors are shown in Figures 81–84

Figure 81. An example of a PVC wall covering on a stud wall and PVC floor covering on a sheet subfloor, both with a particle board substrate. The floor covering in this example is continued 60 mm up the walls (corresponding to the minimum requirement) and is wire-welded to the PVC wall covering.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 82. . An example of PVC wall covering on a stud wall with plasterboard and PVC floor covering on a particle board subfloor. The wall covering overlaps the floor covering by 50 mm. The joint is bonded. The floor covering is continued 150 mm up the walls so that the joint will be 100 mm above finished floor level. In this way, the bonded joint is protected against splashback. Prior to mounting the wall covering, filler has been applied between the floor covering and walls to ensure smooth transitions.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 83. An example of PVC floor covering on a particle board subfloor on a timber joist construction. Falls are constructed by adding wedges to the timber joists. The floor covering in this example is continued 60 mm up the walls (corresponding to the minimum requirement) and is wire-welded to the PVC wall covering.

Floor |

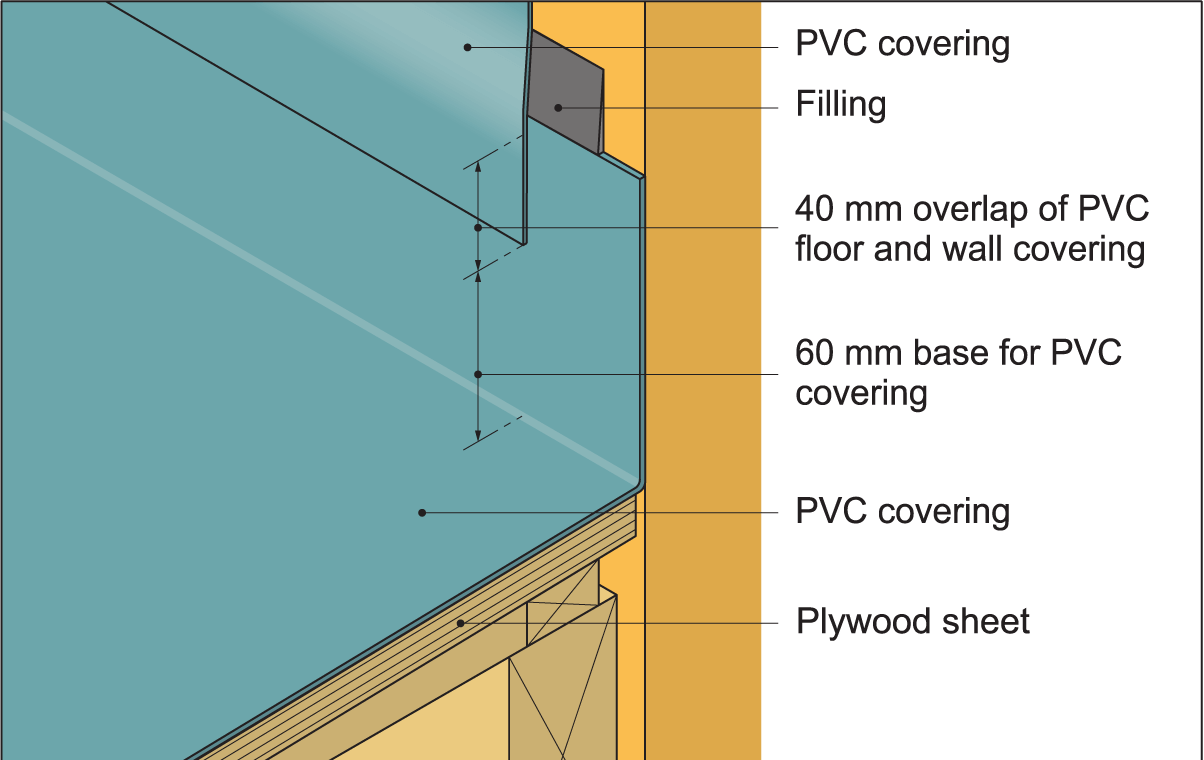

Figure 84. A PVC floor covering on plywood subfloor on timber joist construction. Falls are constructed by adding wedges to the timber joists. In this example, the floor covering is continued 100 mm up the walls. The walls are covered with PVC overlapping the upturned floor covering by 40 mm. The upturn in this example results in a base height of 60 mm.

Floor |

The application area for PVC on walls depends on the substrate (see Tables 6 and 7 in Section 4.1.2, Combinations of Wall Constructions and Waterproofing Systems).

6.3.3 Laying a PVC Floor Covering

PVC floor coverings are laid on a subfloor. Both subfloor and floor covering should be installed by skilled craftsmen with welding certificates (i.e., floor fitters with specialist training in this type of work) (see Section 6.2.1, Prerequisites for Using PVC).

Falls in the subfloor can be created in various ways, depending on circumstances. Normally, either method A or B described in Section 3.3.3, Constructing Falls is used.

As a last resort, in rooms smaller than 2 m2 or in delimited areas (such as shower stalls) falls may be made by filling level floors using a suitable fibrous filler, possibly with an ancillary primer which will form a fixed bond with the floors when curing. The filler must be min. 3 mm thick, which means that the floor outlet will have to be raised slightly above the existing floor surface.

The following requirements must be met when fitting a PVC floor covering:

- The covering must be fully bonded to the subfloor.

- All joints in the covering must be wire-welded.

- No length joints are permitted in shower stalls.

- The number of joints and pipe penetrations in the covering should be kept to a minimum.

- No joints above subfloor sheet abutments.

- Joints in vertical corners must be cut obliquely (see Figure 80 in Section 6.2.1.).

- Joints should be positioned min. 200 mm away from floor outlets.

The PVC floor covering must be continued up the wall and bonded to it. The joint between floor and wall must be watertight. This can be ensured by welding the floor covering with the PVC wall covering or by overlapping a watertight wall covering or paint application with the floor covering (see Figure 80 in Section 6.2.1 and the BYG-ERFA info sheet (43) 96 06 25, Svejsefuger i vådrums PVC-beklædninger og belægninger (Welding Joints in Wet-Room PVC Coverings) (Byg-Erfa, 1996)).

6.4 Watertight Paint Applications/Wet-Room Paint Application Kits

6.4.1 Approvals for Paint Applications

Watertight paint applications for use in humid zones might have an ETA or MK approval, but such an approval is not a requirement. However, manufacturers must always be able to document that the product meets the standards required for obtaining an ETA or MK approval. Such requirements include watertightness, water-vapour impermeability, adhesion, layer cohesion, and resistance to shocks and blows. The requirements for paint application systems are specified in MK 7.00/012, Vægbeklædninger til vådrum. MK prøvnings- og godkendelsesbetingelser (Wall Coverings for Wet Rooms. Conditions for MK Testing and Approvals) (ETA-Danmark, 2014b).

6.4.2 Watertight Paint Applications

In wet rooms with stud walls with gypsum or calcium silicate sheet facings or other types of walls containing organic material, such as wood, watertight paint coverings are only allowed in humid zones.

Watertight paint solutions for use in humid zones on stud walls in wet rooms are kits (i.e., they consist of several prescribed components). Typically, a wet room paint system kit includes primer, waterproofing membrane, glass felt (or glass-fibre fabric) with ancillary adhesive, moisture-resistant glass-fibre filler, and paint for the topcoat (see Figure 85). Often, the waterproofing membrane in a wet room paint system kit is made of glass felt or glass-fibre cloth fixed with special adhesive.

Moreover, watertight paint systems can be used for brick and concrete walls, provided that the manufacturer can document that the kits are suitable for these substrates (see Section 4, Walls).

Manufacturers of watertight paint systems are obliged to provide information on how joints between the painted area and other materials in wet room should be made. Maintenance intervals and methods should also be stated by manufacturers.

6.4.3 Impermeability

Wet room paint system kits act as vapour barriers for outer walls in wet rooms. To prevent moisture from accumulating in stud walls with a watertight paint application, no vapour barrier should be installed behind the plasterboard. Outer walls with stud constructions meet Building Regulation requirements for moisture protection when the Z-value of the watertight paint system on plasterboard is min. 100 GPa s m2/kg. The Z-value indicates the degree of impermeability to water vapour diffusion. Information about the Z-value of specific paint systems should be available from the manufacturer. If the paint is applied too thinly (including adhesive and glass-fibre filler) there is a risk that water and water vapour will penetrate the paint.

6.4.4 Carrying Out the Work

Manufacturer’s instructions (on carrying out joints and penetrations for example), must always be observed, as must the specified materials, quantities, and application deadlines. Materials from different kits should never be combined and wet room paint system kits should never be combined with waterproofing membranes designed for tiled solutions.

Watertight layers should be applied before, or in conjunction with, fixing the glass-fibre fabric or glass felt to the wall.

Fibre-glass cloth or glass felt should have a min. weight of 100 g/m2. Continue the watertight layer min. 30 mm (preferably more) down across the floor’s watertight layer or covering. There must be no pores, holes, or cracks in the finished surface, as these can cause bulking or blistering when the wet room is used.

The thickness of each layer of paint applied should be checked continuously while the work is being carried out. It is easy to gauge the thickness of a wet film of paint using a so-called wet film comb. However, problems may occur when gauging on fibre-glass fabric, as its surface area is structured. Film thickness can also be checked by comparing the measured wall area with the required quantity of weighed or measured tanking membrane and paint.

To protect the paintwork from splashback from the floor, it is advisable to finish it min. 60 mm above floor level. However, it is recommended that the base height be increased to 100 mm and that the watertight floor layer (or covering) be continued min. 130 mm up the walls to obtain 30 mm overlap with the paintwork (see Figures 86 and 87).

6.4.5 Painting the Upper Parts of Walls

Formerly, it was common practice to tile inorganic walls to a height of 1.8 or 2.0 m and then paint the upper part. In the case of stud walls and walls containing inorganic materials, this is not permitted in the wet zone (i.e., no paintwork is permitted on the upper parts of walls in shower stalls and above bathtubs). However, applying watertight paint on those parts of the wall which are above standard room height is permitted (i.e., areas more than 2.3 m above finished floor level).

Figure 85. An example of typical work processes when watertight paint is applied to a sheeting substrate.

- Filling and sanding.

- Priming.

- and 4. Fixing the fibre-glass fabric using special adhesive, possibly saturating the fabric with an extra amount of special adhesive.

- Applying or re-applying filler or glass-fibre filler.

- 7, and 8. One or more finishing coat(s) of paint.

Figures 86 and 87 show examples of joints between floor and walls with watertight paint applications (i.e., applications meeting the requirements of an ETA or MK approval).

Figure 86. An example of joints between a painted stud wall and floor with PVC covering on a particle board substrate. The watertight paint application overlaps the PVC floor covering by 30 mm. Filler has been added to the joint to get a smooth transition with the covering. Mesh reinforcement strip is placed over the filler and the overlap to achieve strong adhesion between the watertight paint application and the floor waterproofing membrane. The floor covering is continued 130 mm up the walls so that the paint system finishes 100 mm above finished floor level. On stud walls and walls containing organic material, paint must only be applied in humid zones.

Floor |

Wall in wet zone |

Væg i fugtig zone |

Figure 87. An example of a joint between a painted stud wall and tiled floor on a structural plywood substrate. In this example, the floor membrane is continued 130 mm up the walls. The watertight paint system finishes on the upper side of the base tiles, overlapping the watertight layer in the tiled floor by min. 30 mm. The joint between base and paint application is usually finished with an acrylic sealant joint, or a similar solution. Filler is added to the joint between the waterproofing membrane and sheet covering to achieve a smooth transition. On stud walls and walls containing organic material, paint must only be applied in humid zones.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 88. An example of a PVC floor covering (on screed on a concrete deck construction). In the example shown, the PVC floor covering is continued 130 mm up the walls and the paint application overlaps the upturned covering by 30 mm. This results in a base height of 100 mm, which protects the overlap joint from splashback

Floor |

Wall in wet zone |

Wall in humid zone |

For maintenance purposes, painted walls should be avoided in wet zones.

On stud walls and walls containing organic material, paint must only be applied in humid zones. Paint applications should also be avoided on inorganic substrates in wet zones or should only be used in load class L.

Figure 89. An example of tile covering bonded to screed on a watertight concrete deck construction. The joint between floor and walls must be executed using watertight flashing as shown. Thus, the flashing should continue min. 100 mm across the concrete deck and min. 100 mm up the walls. In the example shown, the flashing is continued 150 mm up the walls. When the paint application overlaps the upturned covering by 50 mm, a resulting base height of 100 mm is obtained, which protects the paint application against splashback.

Floor |

Wall in wet zone |

Wall in humid zone |

For maintenance purposes, painted walls should be avoided in wet zones.

6.4.6 Maintenance

Painted wet rooms should be checked regularly. In dwellings, maintenance intervals will typically be 4–8 years for standard use.

Painted surface areas should be kept clean and dry. If the painted surface gets wet, it should be wiped dry and cleaned regularly with care. The surface areas must be repainted proactively before leakages occur in the surface. The manufacturer is obliged to provide information on maintenance methods.