4 Walls

Walls in wet rooms can be divided into the following three main types:

- Heavy walls on inorganic substrate (e.g., concrete, lightweight concrete, or brick) (see Section 4.2.)

- Stud walls on sheeting substrate (see Section 4.3.)

- Renovation of existing walls (see Section 4.4.)

This section discusses these main types, how wall and waterproofing systems can be combined, and in which load classes the constructions can be applied.

4.1 Application Areas and Waterproofing Systems

4.1.1 Application Areas

Walls in wet rooms must be secured against deformation and cracking to a greater extent than walls in dry rooms. This means that they must be more rigid than walls in dry rooms and that stable support must be provided for new walls. Furthermore, any unintentional load on non-supporting walls should be avoided. Sloping walls always count as walls.

A distinction is made between heavy- and light-grade walls:

- Heavy-grade is the term used for walls made of inorganic materials, such as concrete, lightweight concrete, or brick walls. Heavy-grade walls can be used in all conditions.

- Light-grade is the term used for stud walls (e.g., a steel frame with sheet facing). Light-grade wall constructions exposed to water can result in serious secondary damage and potential leakages must therefore be detected immediately to curb the extent of such damage. Moisture must not be able to accumulate in constructions containing sensitive materials. Walls must not be constructed as stud walls in load class H (i.e., where water exposure is anticipated to increase or become more frequent than is normal for dwellings, or where major mechanical loads are expected to occur) (see Section 4.1.2, Combinations of Wall Constructions and Waterproofing Systems).

4.1.2 Combinations of Wall Constructions and Waterproofing Systems

The choice of waterproofing kit and surface finish for wet room walls depend on the construction build-up used. The range of options for waterproofing systems is greater for constructions of inorganic materials which are considered intrinsically watertight. The combination options for wall constructions and waterproofing systems are listed in Tables 6 and 7.

When using a combined floor construction and waterproofing system classed lower than the actual wet room class, the construction is regarded as having a greater risk of sustaining moisture-induced damage (see Bekendtgørelse om kvalitet, OPP og totaløkonomi I offentligt byggeri (The Statutory Order on Quality, OPP, and Total Economy in Public Construction) (Danish Ministry of Climate, Energy, and Construction, 2013)). Should one decide to implement the proposed assembly, any special measures implied by this choice must be clarified (e.g., more rigorous inspections during construction and increased checks and maintenance).

Table 6. Combinations of wall constructions and waterproofing systems for wet zones. For each combination, the applicable load class a given combination can be used for is stated (e.g., a stud wall with gypsum-board sheets and PVC facing can be used in load classes L and M). The load classes are explained in more detail in Section 1.6, Load Classes. Combinations with green and yellow colour markings can be used, but yellow can only be used under certain conditions.

Waterproofing Wall Construction | MK-Approved Tile Setting System with Membrane | PVC | Min. 0.20 mm PE Foil or 1 mm Waterproofing Membrane as Substrate for Sheet or Board Covering | Tile Setting System Without Membrane/Paint. Requirements for MK Approval Must be Met and Documented 1) | None (i.e., a water-repellent tiled/painted surface, or similar) 2) |

Concrete cast on site | |||||

Concrete/lightweight concrete slabs/blocks | |||||

Brick, etc. | |||||

Stud wall with 'watertight' sheets 5) | |||||

Stud with calcium silicate sheets | |||||

Stud with cementitious sheets | |||||

Stud with wet-room plasterboard | |||||

Stud with fibre plasterboard | |||||

Stud wall with plywood/particle board sheets | |||||

Stud wall with laminate sheets 6) | |||||

Stud wall with board facing | |||||

Slag plate wall, Monier partition wall | |||||

Board partition wall, Half-timbered wall |

Wall constructions below the double lines are often used in renovation projects. They are not suitable for wet zones when building new bathrooms.

- The column applies to tile setting systems without membranes (see definition of tile setting systems in Section 6.1. and paint/wet room paint application systems in Section 6.3.)

- If exposed to moisture, brick or lightweight concrete walls will transport moisture to adjacent rooms. This column applies to tiles fixed in ordinary tile adhesive, which will be less protective against water infiltration than solutions using a different waterproofing system. Walls should therefore be waterproofed prior to tiling.

- Tiles can be used. Paint systems on inorganic substrates should be avoided if possible, or should only be used in load class L, because painting in wet zones involves much maintenance, which increases with the load.

- It is feasible to install PVC facing on plastered brick walls to ensure watertightness, but it is difficult/impossible to do this and achieve an aesthetically satisfying result because all irregularities are visible through the facing.

- 'Watertight' should be understood as MK-approved panels with a surface or surface covering which is intrinsically watertight (e.g., plastic coating). In addition, they must be given a watertight coating or be installed on a watertight substrate.

- Laminate sheets include both solid laminate sheets and sheets with a laminate covering

Table 7. Walls in humid zones. Combinations of wall constructions and water proofing systems. For each combination, it is stated in which load class a given combination can be used (e.g., a stud wall with plasterboard and PVC covering can be used in load classes L and M). The load classes are explained in more detail in Section 1.6, Load Classes. Combinations with green and yellow colour markings can be used, but yellow can only be used under certain conditions.

Waterproofing Wall Construction | MK-Approved Tile Setting System with Membrane | PVC | Min. 0.20 mm PE Foil or 1 mm Waterproofing Membrane as Substrate for Sheet or Board Covering | Tile Setting System Without Membrane/Paint. Requirements for MK Approval Must be Met and Documented 1) | None (i.e., a water-repellent tiled/painted surface, or similar) |

|---|---|---|---|---|---|

Concrete cast on site | |||||

Concrete/lightweight concrete slabs/blocks | |||||

Brick, etc.. | |||||

Stud wall with 'watertight' sheets 2) | |||||

Stud wall with calcium silicate sheets | |||||

Stud wall with cementitious sheets | |||||

Stud wall with wet-room plasterboard | |||||

Stud wall with fibre plasterboard | |||||

Stud wall with plywood/particle board sheets | |||||

Stud wall with laminate sheets | |||||

Stud wall with board facing 3) | |||||

Slag plate wall, Monier partition wall | |||||

Board partition wall, Half-timbered wall |

Wall constructions below the double lines are often used in renovation projects. At minimum, all wall types should be levelled and the sheeting installed prior to tiling or installing PVC facing. Alternatively, an additional wall can be erected in front of the old wall (see Section 4.4, Using Existing Interior Walls). Board partition walls and half-timbered walls must only be used if given a sheet covering, which is subsequently waterproofed.

- The column applies to tile setting systems without membranes (see definition of tile setting systems in Section 6.1. and paint/wet room paint systems in Section 6.3.)

- 'Watertight' should be understood as MK-approved panels with an intrinsically watertight surface or surface coating such as a plastic coating.

- Laminate sheets include both solid laminate sheets and sheets with a laminate covering.

- Adhesion must be documentable.

- Tiles can be used. Painting on inorganic substrates should be limited to classes L and M because considerable maintenance must also be anticipated in class H humid zones.

- It is feasible to install PVC facing on plastered brick walls to ensure watertightness, but it is difficult/impossible to do this and achieve an aesthetically satisfying result because all irregularities are visible through the covering

4.2 Heavy-Grade Walls

4.2.1 Build-Up

Heavy-grade walls usually consist of concrete slabs, brickwork, or lightweight concrete slabs/blocks. Traditionally, inorganic constructions have been considered intrinsically watertight, which is usually correct for commonly used concrete types whose joints and casting joints are tight. By contrast, once brick or lightweight concrete walls absorb moisture, this moisture is transported to adjacent rooms or building parts (e.g., timber joist constructions). Such walls should therefore always be waterproofed prior to tiling (e.g., using an ETA or MK approved tile setting system).

Preparing Wall Areas

Prior to installing a facing, the wall area must be prepared. All slab joints and wall-to-wall joints must be waterproofed and possibly reinforced. Special care must be taken with joints between new and old walls and between exterior and interior walls. Brick walls must be plastered to get a plane surface area sufficiently strong to support the subsequent facing. Transitions between floor and walls must be flashed to waterproof them min. 100 mm out across the floor and min. 100 mm up the walls measured from finished floor level.

Wall-Covering Materials

Tiles are commonly used as covering for heavy-grade inorganic walls. Watertight PVC facing can also be used but is less common. This is because even tiny irregularities in the surface area will show through the facing.

Tiling

Tiles are installed using flexible tile adhesive so that minor movement from residual shrinkage and moisture and heat exposure is compensated for. If the wall has been waterproofed with a membrane from an approved tile setting system, tiles are fixed as specified in manufacturer's instructions, including using the tile adhesive stipulated in the approved tile setting system.

Formerly, tiles were often fixed directly in cement-lime mortar (corresponding to mortar KC 35/65/650). The method is still applicable for inorganic walls where no waterproofing membrane is used. It is particularly suitable if using tiles of varying thickness or with an uneven reverse side.

The traditional method entails fixing tiles directly to a raw brick wall with a blob of mortar for each tile. This method is no longer applicable in wet rooms. This is because a cavity is left behind the tiles which, in unfortunate circumstances, may cause water to be transported into the brickwork (or other substrate). Furthermore, microorganisms, including mould fungus may develop in these cavities.

Tiled walls are sealed with tile grout. Joints between floor and walls (or other surfaces) can be sealed with flexible grout if only minor movement is anticipated. This is likely to be the case in well-constructed wet rooms where walls and floors are properly joined. Where major movement is expected, acoustic conditions require compensation, or where minor cracks in the sealant is unacceptable for hygienic reasons, resilient sealant such as silicone (for wet room use) is used (see Section 7.1, Joints).

4.2.2 Concrete Walls

Joints must remain watertight. This applies to joints between concrete slabs and between concrete walls and other walls, floors, and ceilings. Waterproofing of joints can be achieved with mesh reinforcement to which a liquid waterproofing membrane is applied. Alternatively, special sealant tape can be used.

Prior to applying a water-repellent surface finish, form coating

or other impurities must be removed to ensure adequate adhesion. Concrete walls which have not cured sufficiently should not be tiled

to any great extent, as shrinkage can be damaging and can cause tiles to crack. The curing time is relative to the concrete composition, thickness, temperature, and moisture conditions. As a rule, a minimum of 2–3 months should elapse from casting the concrete to fitting the tiles.

4.2.3 Lightweight Concrete Walls

Lightweight concrete walls can be made of cellular concrete or lightweight aggregate concrete.

Tiling of lightweight aggregate concrete should not be done until the moisture content has dropped to 4–8 percent by weight, depending on the density. Drying will normally last between 3 weeks and 2 months in a closed-off, heated house, depending on the drying method used. Residual moisture content should be determined prior to starting the tiling process. Information on drying processes and measuring residual moisture content is available from lightweight aggregate concrete manufacturers.

Cellular concrete will normally dry in about 3 weeks in a closed-off house heated to 20 degrees or more.

Since lightweight aggregate concrete shrinks while curing, joints must be designed to remain watertight. This applies to joints between concrete slabs and between lightweight concrete walls and other walls, floors, and ceilings.

Waterproofing of joints can be done by mesh reinforcement to which a liquid waterproofing membrane is applied, or by using special sealant tape.

After drying and before the wall covering is applied, lightweight concrete walls must be prepared (e.g., using a cementitious grout filler). Furthermore, the walls (especially in the wet zone) must be waterproofed prior to fixing the tiles. For example, this can be achieved using an ETA or MK approved watertight tile setting system with a min. 1.0 mm thick waterproofing membrane.

The approval often covers stud-wall applications with sheet cladding. One should ensure that the system is applicable on a substrate of lightweight concrete before using it.

4.2.4 Brick Walls

Inden fliseopsætning skal murede vægge pudses, så de får en jævn, glat overflade. Især i vådzonen bør væggene vandtætnes, før fliserne sættes op. Det kan fx ske ved at anvende et ETA- eller MK-godkendt vandtæt flisesystem med en mindst 1,0 mm tyk vandtætningsmembran. Godkendelsen gælder ofte for brug på skeletvægge med pladebeklædning. Det skal sikres, at systemet kan benyttes på underlag af tegl/puds.

4.3 Stud Walls

4.3.1 Application Area

The application area for stud walls depends on the wall construction (i.e., spacing of studs, how many sheet layers, sheet thickness, and other factors) and on the waterproofing principle used (see Tables 6 and 7 in Section 4.1.2, Combinations of Wall Constructions and Waterproofing Systems). The walls must be watertight from floor to ceiling or at least to standard ceiling height (which is 2.3 m above finished floor level).

Stud walls can be waterproofed using one of the following solutions:

- A watertight facing (such as a 1.0 mm waterproofing membrane forming part of an ETAG- or MK-approved tile setting system, or a min. 1.5 mm PVC facing)

- A watertight paint system

- A watertight layer of foil underneath a moisture-proof sheet or board facing

A watertight facing or paint system must be implemented as described in Section 6, Watertight Floor Coverings, Facing, and Paint Systems.

A watertight layer of foil, installed as part of the wall construction, must be polyethylene foil (PE foil), min. 0.20 mm thick, or another quality foil with a documented long lifespan. The quality of plastic, rubber, or bitumen-based foils can be documented by demanding that the foil meet the requirements for moisture barriers in SPCR 128 (SP, 2004) and SP technique 1380 (SP, 2005).

Foils of recycled plastic cannot always be expected to have a long lifespan.

Only One Watertight Layer – No Vapour Barrier in Exterior Wall

Stud walls in wet rooms must only have one watertight layer. This ensures that water from leakages can escape, avoiding an accumulation of moisture and subsequent damage to the wall. In exterior walls constructed as stud walls, a vapour barrier is normally installed on the warm side of the insulation (e.g., between the stud and the interior facing). In wet rooms with exterior walls constructed as stud walls, the watertight facing or paint will also act as a vapour barrier. To avoid moisture accumulating between the vapour barrier and the wall’s watertight layer, the typical vapour barrier should be omitted (see Figure 56).

Figure 56. In wet rooms, the watertight wall covering also functions as a vapour barrier. Consequently, no further vapour-blocking layers must be installed behind moisture-sensitive sheet facings like gypsum board or wood-based sheets, as this will introduce a risk of moisture accumulation in the material. For exterior walls, this means that the vapour barrier behind sheet facings must be omitted, or that moisture-resistant sheets should be used.

Watertight tile coverings and paint systems can be assumed to meet Building Regulation requirements for moisture protection of exterior stud walls when the facing or paint system has a Z-value of min. 100 GPa s m2/kg. A moisture assessment of the whole wall construction should always be made to ensure that no layers are incorporated into the wall which may cause condensation, such as a tight wind barrier.

However, two watertight layers in a construction can be used if:

- it can be ascertained that no moisture will accumulate between the two watertight layers (for example, a watertight PVC covering can be used directly on top of sheeting with a watertight surface).

- the material enclosed between the two watertight layers is water-resistant. Water must not penetrate to the underlying construction. For example, calcium silicate sheets can be mounted on a vapour barrier of 0.20 mm PE foil and then receive a watertight tile covering. Sheeting used between two membranes must be resistant to mould

4.3.2 Constructing Stud Walls

Rigidity of Stud Walls

In wet rooms, stud walIs are required to have greater rigidity than stud walls in dry rooms to counteract damaging deformation and failure in watertight layers. Enhanced rigidity can be obtained with less spacing between studs, stronger studs, a double layer of sheets, and increasing sheet thickness. Requirements are dependent on the desired facing or treatment.

Sheets are normally installed on a steel or timber stud. All sheet edges must be supported. Stud walls must be constructed with stud spacing, sheet thickness, and screw spacing as stated in Sections 4.3.3 and 4.3.4.

Reinforcement for Fittings and Penetrations

When installing fixtures and fittings, equipment, and other elements which subject the walls to significant loads, measures must be taken to ensure that the loads are absorbed without the risk of failure occurring in the watertight layer.

A wall-hung toilet or washbasin must be installed on a mounting frame bolted to the floor or subfloor. The mounting frames should be constructed with protruding bolts long enough for the sanitary fixtures to be mounted on the sheet facing after the waterproofing system has been installed.

If special loads are planned (e.g., fitting arm rests), reinforcement must be installed, potentially in the form of securely fixed nogging or steel mounting plates (e.g., fastened between two studs). It might be necessary to erect extra studs for additional reinforcement.

The position of the shower slide bar, fixtures, and other elements, should be planned prior to installing the sheet facing. This helps ensure that reinforcement is added behind the sheets (e.g., nogging or a mounting plate fixed to the studs in the stud).

If load is transmitted to the stud walls from adjacent building parts, this could lead to deformation of the walls with the ultimate risk of leakages in the watertight layers. Connections should therefore be constructed to enable movement to be absorbed without the risk of failure in the watertight layers, coverings, and paint systems. Near the ceiling, special ceiling rails can be used to absorb deflections from the deck, and sealant can be applied between the walls to absorb movement in materials and constructions. Alternatively, the walls can be dimensioned for the loads.

Figure 57. The position of studs and nogging must be planned so that the incorporation of mounting frames (for the toilet and washbasin) and piping (for water supply and discharge) can be run without weakening the stud walls (e.g., due to battens being cut). Mounting frames for wall-hung toilets must be fixed to the deck or subfloor.

4.3.3 Sheets for Watertight Facing

Possible sheet substrates for watertight facing could be:

- wet room plasterboard,

- fibre plasterboard,

- calcium silicate sheets,

- cementitious sheets, or

- plywood or particle board.

Table 8 lists inter-related sheet thickness and spacing for studs and screws.

Table 8. An overview of sheet thickness and spacing for studs and screws for stud walls with sheets as substrates for watertight facing.

Facing | Wet-Room or Fibre Plasterboard | Cementitious Sheet | Calcium Silicate Sheets 1) | Plywood or Particle Board 2) | Plywood or Particle Board 2) | |

|---|---|---|---|---|---|---|

Min. thickness [mm] | 2 × 12,5 | 15 | 2 × 12.5 | 2 × 12 | 15 (plywood) 16 (particle board) | 12 |

Max. spacing of studs in stud [mm] | 450 | 300 | 450 | 450 | 600 | 400 |

Max. screw spacing in stud along edges [mm] | 200 | 250 | 200 | 200 | 150 | 120 |

Max. screw spacing in stud in intermediate supports [mm] | 300 | 250 | 300 | 300 | 150 | 120 |

- The rearmost sheets could be made from wet room plasterboard, for example.

- Plywood according to EN 636 – Parts 1, 2, or 3 (Danish Standards, 2012), Particle board according to EN 312 – Parts 1, 5, 6, or 7 (Danish Standards, 2010).

Wet Room Plasterboard

Wet room gypsum board is the term used for special plasterboard with a silicone-impregnated core and a higher density than normal plasterboards. A double layer of boards must be used throughout the room. The sheets must be marked R and D according to DS/EN 520 (Danish Standards, 2009a).

Wet room plasterboards must meet the following requirements:

Sheet thickness: | ≥ 12.5 mm |

Density: | > 800 kg/m3 |

Flexural strength: | > 8.1 MPa on the front and 3.4 MPa on the back |

Resilience module: | > 4000 MPa |

Linear expansion: | < 0.04 % for changes from 50 % RH to 90 % RH |

Mounting:

- Mount sheets on a zinc-coated steel or timber stud with the studs spaced out max. 450 mm centre-to-centre.

- Use 70 mm steel profiles or a timber stud, with studs measuring min. 45 × 70 mm. To avoid joint-on-joint alignment between the two layers of boards, they must be offset to equal the distance between two studs (see Figure 58).

- Screw-fix boards with corrosion-proof drywall screws.

- Screw spacing in the outside layer must be max. 200 mm along the edges and max. 300 mm in intermediate supports. Screw-fix to all studs.

Figure 58. Mounting wet room plasterboard on steel studs. A double layer of sheets must be used throughout the room. The sheets are mounted with staggered joints. The same mounting method is used for a timber stud.

Fibre Plasterboard

Fibre gypsum board is the term used for plasterboards with fibre reinforcement without a carton-covered surface. Use either a double layer of 12.5 mm boards in the whole room or a layer of 15 mm boards with reduced stud spacing.

Fibre plasterboards for stud walls in wet rooms must meet the following requirements:

Board thickness: | ≥ 12.5 mm (15 mm when using one layer) |

|---|---|

Density: | > 1100 kg/m3 Flexural |

strength: | > 4 MPa |

Linear expansion: | < 0.04 % for changes from 65 % RH to 85 % RH according to DS/EN 15283-2, Plasterboards with fibrous reinforcement – Definitions, requirements and test methods - Part 2: Gypsum fibre boards (includes Amendment A1:2009). |

Mounting:

- Install boards on a zinc-coated steel or timber stud. Use 70 mm steel profiles or a timber stud with studs measuring min. 45 × 70 mm.

- If using a double layer of boards, the spacing between studs must be max. 450 mm centre-to-centre. To avoid joint-on-joint alignment between the two layers of sheets, they must be offset to equal the distance between two studs (see Figure 58).

- If only a single layer of boards is used, the spacing between studs must be reduced to max. 300 mm centre-to-centre.

- Screw-fix sheets with corrosion-proof drywall screws. Screw spacing along edges and in intermediate supports must be max. 250 mm. Screw-fix to all studs.

Calcium Silicate Sheets

Calcium silicate sheet is the term used for fibre-reinforced sheets made of cement, silicon oxide, hydrated lime, and similar materials.

As opposed to wooden or plasterboards, calcium silicate sheets will tolerate moisture exposure. Accordingly, they are suitable for wet room wall constructions. The sheets are usually reinforced with approx. 5 % fibre such as cellulose fibres.

Calcium silicate sheets must meet the following requirements:

Sheet thickness: | ≥ 12 mm |

Density: | > 850 kg/m3 |

Flexural strength: | > 6 MPa |

Linear expansion: | < 0.1 % for changes from 50 % RH to 90 % RH. |

Mounting:

- Install sheets on a timber- or zinc-coated steel stud.

- Use 70 mm steel profiles or a timber stud with studs measuring min. 45 × 70 mm.

- The spacing of studs must be max. 450 mm centre-to-centre.

- Install calcium silicate sheets in two layers. Alternatively, a finishing layer of calcium silicate sheets can be mounted on a first layer of 12.5 mm wet room or fibre plasterboard.

- Fix boards to substrate with corrosion-proof particle board screws. Screw-fix the boards to all studs. Calcium silicate sheets functioning as substrate for tiles or paint applications are screw-fixed with self-tapping screws spaced out max. 200 mm along edges and max. 300 mm in intermediate supports.

Cementitious Sheets

Cementitious sheet is the term used for reinforced sheets made of cement with a (light) mineral aggregate (apart from calcium silicate sheets). The reinforcement could comprise evenly distributed fibres or mesh reinforcement placed on the exterior of the sheets.

Like calcium silicate sheets, cementitious sheets can tolerate moisture exposure without failing.

Cementitious sheets must meet the following requirements:

Sheet thickness: | ≥ 12.5 mm |

|---|---|

Density: | > 850 kg/m3 |

Flexural strength: | > 6 MPa |

Linear expansion: | < 0.1 % for changes from 50 % RH to 90 % RH. |

Mounting:

- Install sheets on a timber- or zinc-coated steel stud.

- Use 70 mm steel profiles or a timber stud with studs measuring min. 45 × 70 mm.

- The spacing of studs must be max. 450 mm centre-to-centre.

- Install cementitious sheets in two layers. Alternatively, a finishing layer of cementitious sheets can be mounted on a first layer of 12.5 mm wet room or fibre plasterboard.

- Fix sheets to substrate with corrosion-proof particle board screws. Screw-fix to all studs. Cementitious sheets functioning as substrate for tiles or paint applications are screw-fixed with self-tapping screws spaced out max. 200 mm along edges and max. 300 mm in intermediate supports.

Plywood or Particle Board

Wooden sheets (such as 12 or 15 mm thick plywood and 12 or 16 mm thick particle board) can be used in one layer for stud walls in wet rooms. The sheets must be CE marked according to DS/EN 13986 (Danish Standard, 2004) and graded for stress-bearing use in the quality classes listed in Table 8. Wooden sheets can only be used as substrate for PVC.

Mounting:

- Install sheets on a timber- or zinc-coated steel stud. Use a timber stud with studs measuring min. 45 × 70 mm or 70 mm steel profiles. The spacing between studs must be max. 400 mm for 12 mm sheets and 600 mm for 16 mm particle board or 15 mm for plywood sheets.

- Screw-fix wooden sheets with particle board screws spaced out the equivalent of max. 10 times sheet thickness.

- Make sure that all sheet edges are supported.

Moisture-induced movement in wooden sheets is greater than in other sheeting suitable for wet room walls. Sheet edges should therefore have approx. 2 mm of clearance in inward corners, allowing sheet expansion after mounting to be absorbed (see Figure 59).

Figure 59. Clearance in corners. Wooden sheets must not be mounted with tight-fitting joints in corners but should normally have a clearance to adjoining building parts of min. 2 mm..

4.3.4 Sheet Covering on Watertight Substrate

The following can be used as watertight substrates:

- min. 0.20 mm PE foil,

- another quality membrane with documented long lifespan,

- min. 1.0 mm waterproofing membrane from an ETA- or MK-approved tile setting system.

The following can be used as covering on watertight layers:

- calcium silicate sheets,

- calcium silicate sheets with plastic laminate,

- particle board with plastic laminate,

- boards.

Table 9 lists corresponding sheet thicknesses, spacing of studs, and screws for stud walls with a watertight layer of PE foil. Use stainless-steel screws when fixing sheet covering on a watertight layer.

Table 9. Sheet thicknesses and spacing of studs and screws in stud walls with a watertight layer of PE foil.

Facing 1) Silicate | Calcium Sheets | Calcium Silicate Sheets with Plastic Laminate | Particle Board with Plastic Laminate | Board Facing | |

|---|---|---|---|---|---|

Unvented | Vented | ||||

Min. thickness [mm] | 2 × 12 | 12 | 10 | 15 | 21 |

Max. spacing of studs, steel, or timber stud [mm] | 450 | 450 | 300 | 600 | 600 |

Max. screw spacing in stud along edges [mm] | 200 | 400 | 200 | 2) | 2) |

Max. screw spacing in stud between supports [mm] | 300 | 400 | 200 | 2) | 2) |

- Possibly combined with plasterboard.

- Boards are screw-fixed to nogging or support rails per 600 mm (possibly nailed).

Calcium Silicate Sheets

Calcium silicate sheets are moisture resistant and can therefore be used as facing on a waterproofing membrane (such as min. 0.20 mm watertight foil mounted on a stud wall on a substrate of 12 mm calcium silicate sheets or 12.5 mm wet room or fibre plasterboards).

Mounting:

- Use timber or zinc-coated steel with studs spaced out max. 450 mm. for wall studs

- Use 70 mm steel profiles or timber with studs measuring min. 45 × 70 mm.

- Fix the first sheet layer to the substrate with particle board screws. Screw-fix the sheets to all studs.

- Fit waterproofing membrane to substrate sheets (e.g., min. 0.20 mm PE foil). Make sure the membrane fully covers the walls.Make foil joints over studs with min. 100 mm clamped overlaps. Bond or tape for additional security.

- At the floor level, the foil must overlap the floor’s watertight layer or the floor covering by min. 50 mm. This is partly to ensure that any water on the foil is drained onto the floor’s watertight layer and partly to ensure that the joint is clamped by the final layer of sheets (see Figure 60).

- Screw-fix the calcium silicate sheets (functioning as substrate for tiles or paint applications) with corrosion-proof particle board screws spaced out max. 200 mm along edges and max. 300 mm in intermediate supports.

Since calcium silicate sheets are moisture-resistant, an ordinary tile covering or paint system can be used. Paint should only be applied in humid zones, however. Consequently, no ETA- or MK-approved tile setting systems or paint systems are required. In exterior walls, the watertight PE foil acts as a vapour barrier. ETA- or MK-approved tile setting systems used in conjunction with calcium silicate sheets mounted on watertight foil provide an extra watertight finish.

Calcium Silicate Sheets with Plastic Laminate on Watertight Foil

Calcium silicate sheets with a factory-made plastic laminate surface can be used as ready-made facing when installed on a watertight membrane (e.g., min 0.20 mm PE foil).

Mounting:

- Install substrate and watertight layer as described for calcium silicate sheets.

- Sheet thickness must be min. 12 mm.

- Sheets can be installed on a substrate of 12.5 mm plasterboards or 12 mm calcium silicate sheets with a watertight layer of min. 0.20 mm PE foil.

- Screw-fix sheets with corrosion-proof screws spaced out max. 400 mm along edges and in intermediate supports. Screw-fix to all studs.

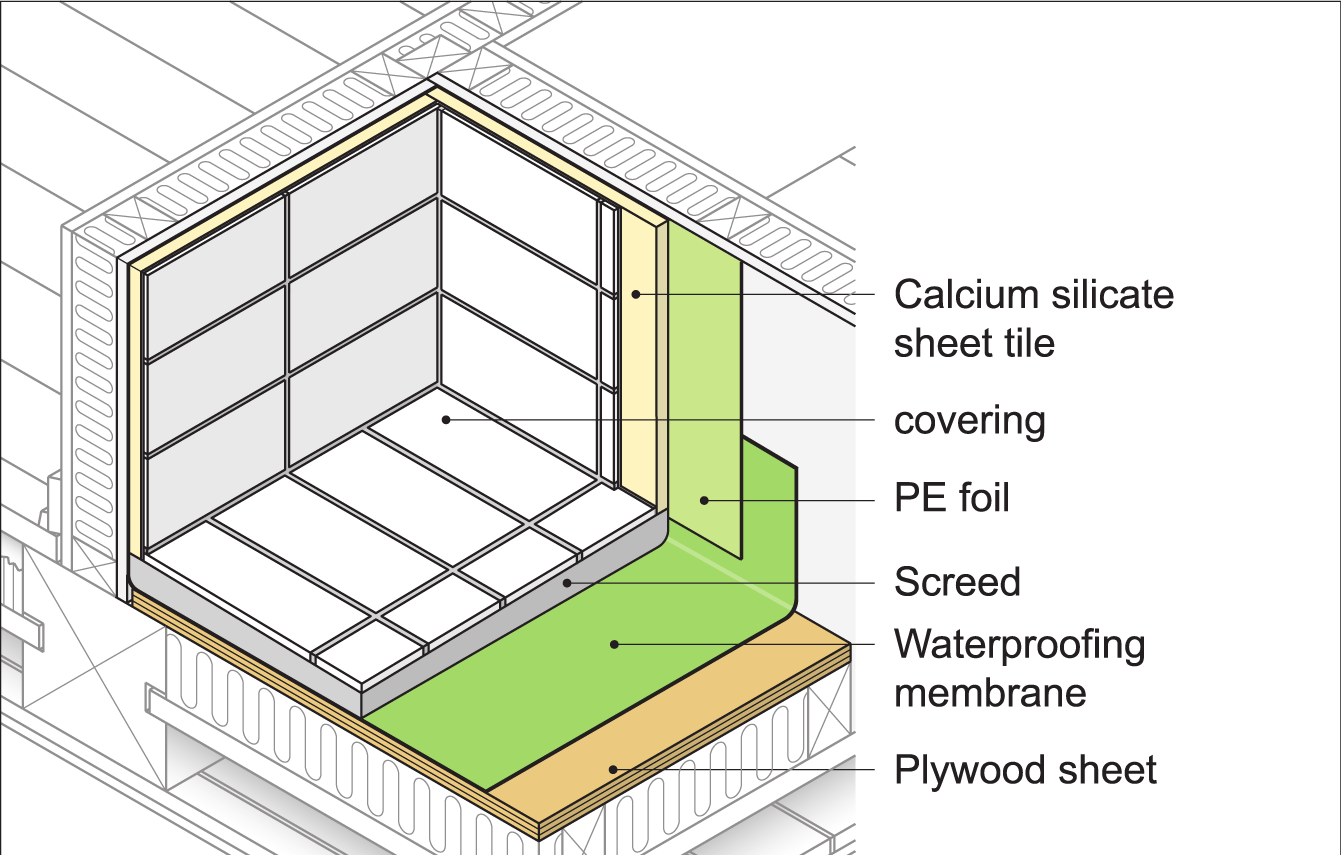

Stud walls with calcium silicate sheets on watertight foil are shown in Figures 60 and 61

Figure 60. An example of a tiled floor on a waterproofing membrane on a plywood subfloor installed on an old timber joist construction. The floor’s watertight layer is continued up to a height of 100 mm above finished floor level. First, wet room plasterboards are installed, followed by a 0.20 mm PE foil (on top). The PE foil is continued 50 mm across the floor waterproofing membrane and is clamped when the calcium silicate sheets are screwed on. Slopes towards the floor gully are built in screed laid on top of the waterproofing membrane.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 61. An example of a tiled floor on a concrete slab with a cast wall base. The watertight layer on the floor is continued up to the top of the base, which is 100 mm above the finished floor level. Calcium silicate sheets are mounted on a steel stud, so that the front side of the first layer of sheets is flush with the front side of the base. A watertight layer of 0.20 mm PE foil has been installed on the first sheet. The PE foil is continued min. 50 mm down and across the upper side of the base. The flashing is clamped when screw-fixing the next layer of calcium silicate sheets. Slopes towards the floor gully are incorporated in the screed which is laid before fitting the waterproofing membrane. Joints between walls and floor and individual walls are sealed with flexible tiling grout.

Floor |

Wall in wet zone |

Wall in humid zone |

Particle Board Sheets with Plastic Laminate on Watertight Foil

Particle board sheets with a factory-made plastic laminate surface can be used as ready-made facing when installed on a watertight foil layer. Sheet thickness must be min. 10 mm and manufacturers must be able to document that the plastic laminate at minimum meets the requirements for type 2 in DS/EN 438 (Danish Standards, 2005a, 2005b).

To prevent any risk of warping, both sides of sheets must be laminated. Since particle board is sensitive to moisture, all sheet edges must be sealed. Especially near the floor, it is vital that no water can infiltrate the sheets.

Mounting:

- Install the sheets on a substrate of 12.5 mm plasterboard or 12 mm calcium silicate sheets with a watertight layer of min. 0.20 mm PE foil.

- Check the spacing between studs in stud walls with the sheeting substrate. This should be max. 300 mm.

- Check the width of the plastic-laminated sheets. To allow for moisture-induced movement, this should be max. 600 mm.

- Install the substrate and watertight layer as described for calcium silicate sheets.

- Screw-fix sheets with corrosion-proof screws spaced out max. 200 mm along all edges. Alternatively, fix with metal profiles.

The installation must be carried out in accordance with the sheet manufacturer’s instructions.

In wet zones, solid plastic-laminate sheets mounted in metal rails with sealing profiles should be used rather than plastic-laminated particle board.

4.3.5 Board Facing on Watertight Substrate

Board facing can be used as wall finish in humid zones when installed on a watertight substrate. The substrate could be:

- Sheet facing with a waterproofing membrane from a tile setting system carrying an ETA or MK approval.

- PE foil or other membrane in documentable good quality with a long lifespan.

The boards must have tongue-and-groove connections and can be installed either directly on a substrate or with a vented cavity at the back.

If the boards are installed horizontally, the groove-side must face down to minimise the risk of moisture accumulating in the facing.

To protect the boards against splashback from the floor, it is recommended that the facing terminate min. 100 mm above floor level. In this case, the watertight layer or covering on the floor must be continued min. 150 mm up the walls to achieve an overlap of min. 50 mm with the watertight layer on the wall (see Figure 63).

The board facing could be protected with a suitable surface application leaving it more resistant to water and easier to clean.

Board Facing Directly on a Substrate

Boards installed directly on a substrate must be min. 15 mm thick.

The boards are installed on a stud according to the following guidelines:

- The wall stud must be made of timber or zinc-coated steel with studs spaced out max. 600 mm centre-to-centre.

- Use timber studs with min. dimensions of 45 × 70 mm or 70 mm steel profiles

- To improve acoustic conditions, it is a good idea to install a sheet layer (e.g., 13 mm wet room plasterboard prior to installing the board facing, filling the cavity with mineral wool). If no sheet facing is used, the stud must be filled out with mineral wool.A waterproofing membrane should be fitted to the substrate (e.g., of min. 0.20 mm PE foil). On a sheeting substrate, the watertight layer can be a min. 1.0 mm waterproofing membrane from a tile setting system carrying an ETA or MK approval. The membrane must cover the walls completely.

- Join foil layers over studs and secure them with min. 100 mm clamped overlaps. These should be bonded or taped for additional security.

- At floor level, the watertight layers of the walls and floor must overlap min. 50 mm. This is partly to ensure that any water on the foil is drained onto the floor’s watertight layer and, partly, to ensure that the joint is clamped by the final layer of sheets (see Figure 63).

- For vertical board facing, insert nogging in the stud spaced out max. 600 mm centre-to-centre.

- It is a good idea to cut the bottom board off at a slant to get a well-defined drip edge.

Figure 62. Example of board facing installed directly on stud wall substrate with two layers of wet room plasterboard and min. 1.0 mm waterproofing membrane from a watertight tile setting system. The floor is shown as a plywood floor with waterproofing membrane. The membrane on the wall is identical to the one on the floor and they are applied in the same work process. In the horizontal wooden facing, the tongue faces upwards to avoid water accumulation.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 63. Board facing installed directly on stud wall substrate of two layers of wet room gypsum board and 0.20 mm PE foil. The floor is shown as a particle board floor with PVC floor covering. The PVC floor covering is continued min. 150 mm up the walls with welded oblique sections at the corners. The PE foil overlaps the PVC floor covering by min. 50 mm.

Floor |

Wall in wet zone |

Wall in humid zone |

Board Facing with Vented Cavity

If there is a vented cavity behind the board facing, the boards must be min. 21 mm thick.

Installing Board Facing:

Install substrate (including the foil) according to the guidelines for boards installed directly on a substrate. Clamp overlap joints with vertical spacer bars screwed to each stud. Use planed wood measuring min. 21 × 45 mm as spacer bars.

Horizontal board facing can be installed directly on spacer bars spaced out max. 600 mm centre-to-centre.

Screw-fix vertical board facing to horizontal support rails fixed to spacer bars spaced out max. 600 mm centre-to-centre. Use planed wood measuring min. 33 × 43 mm as spacer bars. Screw-fix support rails to spacer bars (e.g., with a corrosion-proof screw in every cross joint). Screw-fix or nail boards to horizontal support rails. To ensure air circulation, finish the facing with a vented cavity approx. 30 mm below the ceiling. The foil must fit tightly to the ceiling covering and be joined to the ceiling vapour barrier, if applicable.

Figure 64. PVC flooring on particle board subfloor laid on wedge-shaped battens on plywood substrate. The plywood is laid on battens screw-fixed to the sides of old joists, making the plywood level with the upper side of the joists. The PVC floor covering is continued min. 150 mm up the walls with welded oblique sections at the corners. The wall is constructed with a timber stud and a layer of 15 mm fibre plasterboard as substrate for 0.20 mm PE foil. The PE foil overlaps the PVC base by 50 mm and the joint is clamped with a batten screw-fixed to the nogging. Vertical 21× 45 mm spacer bars are fitted to the studs in the stud wall to create a vented cavity behind the facing. The wooden facing is screw-fixed on horizontal 33 × 43 mm support rails per 600 mm.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 65. PVC flooring on particle board subfloor laid on wedge-shaped battens on plywood substrate. The plywood is laid on battens screw-fixed to the sides of the old joists, making the plywood level with the upper side of the joists. The PVC floor covering is continued min. 150 mm up the walls with welded oblique sections at the corners. The board facing on the wall is installed on 0.20 mm PE foil fitted to a stud wall with 15 mm fibre gypsum board facing. The boards are screw-fixed directly to nogging per 600 mm between studs. The PE foil overlaps the PVC base by 50 mm.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 66. Example of tiled floor on timber joist construction with min. 100 mm concrete wall base. At minimum, the height of the base should correspond to the height of the base tiles. The stud wall is clad with a substrate comprising a layer of 15 mm fibre gypsum board that is level with the base. PE foil has been fitted to the substrate. The watertight layer in the floor, or watertight flashing, is continued min. 150 mm up the walls measured from finished floor level and overlapped 50 mm by the PE foil. The overlap joint is clamped by a batten screw-fixed to the bottom wall plate. The wooden facing is constructed with a vented cavity as shown in Figure 64.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 67. An example of a tiled floor on a substrate construction of plywood on timber joists. As tile covering is not intrinsically watertight, the subfloor is completely covered by a watertight layer (membrane). The membrane is continued min. 150 mm up the walls. The facing comprises boards with an underlying watertight layer in the form of 0.20 mm PE foil. The PE foil overlaps the floor membrane by 50 mm. The board facing terminates 100 mm above floor level, protecting it against splashback.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 68. An example of floor covering with PVC on particle board on timber joist construction. Slopes are constructed by firring the timber joists. The PVC flooring is continued 150 mm up the walls. The facing comprises boards with an underlying watertight layer of 0.20 mm PE foil. The PE foil overlaps the floor membrane by 50 mm. The board facing terminates 100 mm above floor level, protecting it against splashback.

Floor |

Wall in wet zone |

Wall in humid zone |

4.3.6 Watertight Sheets

Watertight sheet is the term used for sheets which are intrinsically watertight when installed as wall facing in wet rooms. These can be different in terms of both materials and composition. They must carry an ETA or MK approval that specifies under which conditions they can be used.

If watertight sheets are used in a wet zone, they must be protected by an MK-approved watertight tile setting system with a membrane or a min. 1.5 mm PVC covering in the same way as other sheet covering materials. If stated in the approval, the sheets can instead be installed on a watertight substrate of min. 0.20 mm PE foil.

Requirements for the construction of the walls will be apparent from the ETA- or MK-approved products.

4.4 Using Existing Interior Walls

4.4.1 Criteria for Usage

Old residential housing will often have timber partition walls and half-timbered walls, or other elements that either contain wood or are water-absorbent. When constructing new wet rooms, such existing interior walls can be retained if the strength and rigidity of the walls have been assessed and deemed satisfactory. The rigidity is satisfactory if it matches the rigidity of a stud wall fitted with one layer of wet room plasterboard. The walls must be replaced by new walls or an additional wall if they are deemed too weak or too deformed (e.g., from settlement).

The strength and rigidity of existing walls will normally have to be assessed when examining the existing constructions. The following questions should be answered:

- Is the construction in good condition without cracks or deformations?

- Which material has been used and how thick is the wall?

- Is there any sign of wood decay?

- Are the joints in good condition and is their strength deemed adequate?

- Will significant deformations result if the wall is given a push?

If strength and rigidity are deemed satisfactory, the walls can be waterproofed according to the guidelines in this section. The walls must always be waterproofed to their full extent.

4.4.2 Changing a Wall Into a Wet-Room Wall

Before changing old timber partition walls, half-timbered walls, breeze-slab walls, or similar elements, a stable substrate for the watertight facing must first be installed. On this substrate, sheet facing such as gypsum or calcium silicate panels is installed as substrate for the watertight coverings and treatments described in Section 6, Watertight Floor Coverings, Facings, and Paint Systems. Installation must be performed according to the guidelines in the same section.

A stable substrate can be installed in one of the following ways:

- If the strength and rigidity of the existing wall is deemed satisfactory, the wall can be prepared by realigning it (e.g., by adding boards or battens as firring, and then installing sheet facing).

- If the strength and rigidity of the existing wall is deemed satisfactory and if the walls also seem to be sufficiently planar, sheet facing can be mounted directly on the existing wall.

- If the strength or rigidity is deemed too poor, this can be improved by building a stud construction against the existing wall for the sheet facing. Furthermore, the wall sound insulation can be improved by installing the stud wall as a self-contained additional wall spaced approx. 30 mm from the existing wall and filling the cavity with insulation material.

4.4.3 Timber Partition Walls

Timber partition walls consist of two or three layers of boards. A two-layer timber partition wall is typically constructed as follows:

- First layer: Vertical boards, 31 × 125 mm or 150 mm (5/4 × 5" or 6"). The boards are spaced out approx. 10 mm, nailed to the ceiling board at the top and, at the bottom, to a joist or header.

- Second layer: Boards installed at an angle, 19 × 100 mm (3/4 × 4"). The boards are spaced out approx. 10 mm and nailed to the vertical boards.

Timber partition walls are, as a rule, covered with reed matting and rendered with lime mortar on both sides. The walls will not tolerate water exposure, as the rendering on the boards will crack if the wood expands after being exposed to moisture. Furthermore, high moisture content may cause decay and dry rot (including mould).

Figures 69 and 70 show examples of joints between walls and floors when renovating timber partition walls.

4.4.4 Half-Timbered Walls

Half-timbered walls consist of half-timbering filled out with brickwork. If used as partition walls, they are rendered on both sides. Such walls will not tolerate water exposure, as rendering on top of half-timbering will crack if the wood expands after being exposed to moisture. Furthermore, a high moisture content may cause decay and dry rot (including mould) in the wood in half-timbered structures.

Figure 69. An example of a bathroom constructed using the existing timber joist construction and timber partition walls. There is a tiled floor installed on a plywood substrate with a water proofing membrane applied in liquid form. The membrane is continued min. 150 mm up the walls and the PE foil and the membrane on the existing wall overlap min. 50 mm. The joint is clamped by screw-fixing the calcium silicate sheets. The wall sheets are tiled over with ordinary tile adhesive. On the floor, tiles are bonded to screed laid on a separating film on top of the waterproofing membrane. Wall corners and joints between floor and walls are sealed using resilient sealant. If a pre-fabricated membrane is used for the floor, the membrane must be turned up and folded in the corners. In this case, it will be necessary to remove some of the wall rendering in the corners to ensure that the wall will remain planar after being covered with PE foil and calcium silicate sheets.

Floor |

Wall in wet zone |

Wall in humid zone |

Figure 70. An example of a bathroom that uses an existing timber joist construction and an existing timber partition wall with an additional wall. The tiled floor is constructed with in situ concrete on a timber joist construction. The concrete slab is cast with a base for an additional wall (in front of an existing timber partition wall). Slopes towards the floor gully are incorporated into the screed bed laid on a separating film on top of the concrete slab. The watertight layer in the floor is laid on the concrete slab and continued up to the upper side of the base. The additional wall is constructed using a steel stud with a substrate of 15 mm fibre plasterboard. The additional wall is positioned so that the plasterboard is flush with the waterproofing membrane on the base. PE foil has been installed on the fibre plasterboard, extending down across the base and overlapping the floor’s watertight layer by min. 50 mm. The joint is clamped when screw-fixing the calcium silicate sheets. The wall sheets are tiled using ordinary tile adhesive. The floor tiles are bonded to the screed layer. Wall corners and joints between floor and walls are sealed using flexible tiling grout.

Floor |

Wall in wet zone |

Wall in humid zone |